- Training Courses

- PLC Courses

Training Courses

PLC Courses

5 different training courses in PLC & Micro-controller Systems

| Code | Course Title |

|---|---|

| PLC-1a | Basics of Electric Components for Automatic Control and PLC Applications |

| PLC-1b | Basics and Components of Industrial PLC & Micro-controller Systems |

| PLC-2 | Design, Analysis and Investigation of Industrial PLC Control Systems |

| PLC-3 | Practical applications and Examples of PLC Control Circuits |

| PLC-4 | Advanced Analysis and Applications of PLC Control Circuits |

| PLC-5 | More Applications of Industrial PLC Control Systems |

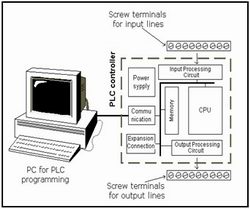

What is a PLC (Programmable Logic Controller) control system?

A PLC is an industrial computer control system that continuously monitors the state of input devices and makes decisions based upon a custom program, to control the state of devices connected as outputs. Almost any production line, machine function or process can be automated using a PLC. The speed and accuracy of the operation can be greatly enhanced using this type of control system.

The PLC consists of the following main parts:

Memory Unit: To store the program of the process and any other setting of the PLC.

Memory Unit: To store the program of the process and any other setting of the PLC.

CPU Unit: It executes the program stored in the memory.

Power Supply Unit: It supplies the necessary power to feed each part of the PLC with its needs (voltage and current), also the power supply unit regulates the electric AC input voltage (110/220 ACV) and removes any spikes in the signal to protect the PLC from damage by higher voltage. Also the power supply unit can supply DC voltage (12/24 DCV) which can be used for supplying other extension units or modules.

Communication Unit: It is responsible of the communication between the PLC and the PC. Communication is needed to program the PLC (stores the program written on the PC in the PLC memory), also communication can be used to send or receive any data required by the user during operations (as set-point, monitoring input/output states by the PC).

Input Processing Unit: Its function is to make electric buffering between input electric signals and inner PLC circuits to protect PLC from high voltages & currents or short circuit faults.

Output Processing Unit: Its main function is to make electric buffering between the inner PLC circuits and the output electric signals to protect the PLC from any high voltages and currents or short circuit faults.

The PC Unit: The PC has many functions:

- Programming of PLC

- Monitoring PLC I/O states

- Sending/Receiving control signals to all the controllers in case of a network

- Storing information in database

- Taking advanced actions in case of alarm or a controller failure

- Distributing loads in case of system overload

The Expansion Connection: For a PLC, it has a main module which performs most of the processing power but it have limited number of inputs and outputs, also it has certain limited features depending on the type and model of the PLC. So, for each type of PLC there are expansion modules that perform extra operations, and the user can add modules as required for process operations. Example: There are expansion modules for extra I/O pins, Modem or Ethernet modules for networks, Sensors or Motor driver modules, Analog I/O modules.

ILOs of courses for PLC and Microcontroller Automatic control Systems & their Applications:

1- Knowledge and Understanding:

- Understand and apply knowledge of basic physics laws and concepts as they apply to PLC and Microcontrollers and to solution of automatic control problems using these systems.

- Understand reading PLC and Microcontrollers schematics and identify system components & design function as well.

- Understand and apply knowledge of Maintenance & Troubleshooting of PLC and Microcontrollers Systems.

- Understand current engineering technologies related to PLC and Microcontrollers Automatic Control Systems.

2- Intellectual Skills: This course helps the students to acquire the ability to:

- Identify, select, describe, and draw the main various components in typical PLC and Microcontrollers schematics and to recognize and comprehend how these components function and interact with each other.

- Follow and participate in a comprehensive interactive &computer-based virtual and multi-media training labs which include system animations, 3-D models and on-line multiple choices quizzes.

- Identify, formulate and solve main basic automatic control problems using PLC and Microcontrollers.

- Design PLC and Microcontrollers circuit, component & schematics to meet required needs within realistic constraints.

- Select appropriate components for modeling and analyzing typical PLC and Microcontrollers Control problems.

- Select appropriate solutions for various multiple choices quiz problems based on analytical thinking.

- Use virtual lab tools & software packages pertaining to PLC and Microcontrollers systems & process control design.

3- Practical and Professional Skills: This course helps the students to acquire the ability to:

- Integrate knowledge of basic physics laws, fluid mechanics concepts, information technology, design, and engineering practice to solve engineering problems of PLC and Microcontrollers Control Systems.

- Employ drawing & professional skills to design & analyse schematics of PLC and Microcontrollers systems & process control circuits.

- Use a wide range of computer applications, technical tools, and techniques including pertinent virtual labs software.

- Implement comprehensive knowledge, understanding, and intellectual skills in solving on-line virtual training labs, exercises, and MCQ problems.

- Prepare and present technical reports and schematics of PLC and Microcontrollers circuits and control systems.

4- General and Transferable Skills: This course helps the students to acquire the ability to:

- Collaborate & Communicate effectively within a lab group/team.

- Work in stressful class and lab environment and within time constraints.

- Demonstrate efficient IT capabilities.

- Manage tasks and lab resources efficiently.

- Search for information and adopt self learning.

- Refer to relevant literature effectively.

All Rights Reserved.